First off, if you are the least bit squeamish, or do not like photos of disgusting things, I'll warn you now, this post is replete with them, but they'll be things like boogers and wounds. I do not warn when one will pop up, either, so proceed at your own risk!

This is not a normal thing for me to post. In fact, everything about me says I shouldn't. However, this could be a bit therapeutic, so I'm going to venture way out into an area where I likely would not.

In late December, while on a drive and following a lengthy descent into a valley, one ear popped, and the other one has not. Thinking I'd had a sinus infection for a long time, I headed into urgent care because I didn't want to remain deaf in that ear. At the time, I was attempting to become a "temple worker" - meaning added service in sacred areas. No one would ever call me back, but they definitely called others back around me. I'd later find that this was one of God's "tender mercies" - because what would come definitely would have impacted everything.

The ear pop failure led to an urgent care visit. That urgent care lead to an ENT (ear, nose, throat) specialist in Mid February. The specialist performed a biopsy on some lumps in the neck.

It was between the urgent care visit and my ENT visit that my spouse also was visiting for some medical issues, which led to a medical appointment for March 29th. I would need to be alert and attentive to her needs for a while, and at this point, all seemed well enough.

After my spouses appointment had been set up, I was pushed into some scans, and in late February, I was diagnosed with Nasopharyngeal Carcinoma (the back of the nasal pharynx). This was a week later determined to be stage 3 (identified fully on March 8th).

On March 15th, I began chemotherapy. I have a three week cycle. The first week is a two-drug "cocktail" infusion. The two drugs are Gemcitabine and Cisplatin. The second week is a single-drug "cocktail". The third week is an "off" week. This three-week cycle coincided perfectly in ways I'd never have expected. My "off week" was going to be.... March 29th. The ONE and ONLY time that I could stop being "sick" and instead focus on my dear sweet spouse!

The drug that is common through weeks one and two is a painful one (Gemcitabine). The best description of that pain is when you get hyper cold, and then someone touches your skin. The entire area feels like that while receiving the drug. It is not comfortable.

The nausea was brutal the first week. I was so bloated that I could not consume liquids because everything wanted to come right back up. The second week, I consumed a lot of fiber before going in for the drugs, and I have continually taking Miralax (the nausea medications don't lend them selves well to regular bowel movements). In fact, I dropped 11 pounds in the first week. I do not recommend this diet, I really don't. I did manage to add a few pounds, but that was short-lived.

On March 24, 2024, my arm became very red, swollen, and painful. One provider diagnosed it as "cellulitis", and another diagnosed it as a blood clot. So, I'm taking a few extra medications hoping this will diminish before I receive more infusions. There is more on this a bit later (it's not cellulitis, nor is it a blood clot). This did abate and disappear after about four days.

Miracle number three might be an "odd" miracle. I struggle with "receiving" service. I've always found myself to be the one stepping in to aid others when they are in need. It's one of my joys. However, it is flabbergasting to realize that these same people who I've aided (and others who I have not) are willing to step in to assist. You definitely see God's hand in your life when you get into a situation like this. He cares, He definitely does.

But why would God allow bad things to happen to people? One of the tenants of my spirituality is "agency". We're born into a life where we can choose to be assholes or angels. If God prevented bad stuff from happening, we wouldn't be able to choose the jerk side of life. We're here to be mortal. We fought for that in the "war in heaven" (the book of Revelation) specifically for our agency. We fought to be here and be mortal. In this situation, feeling gross as I do, I'd still fight that war. I'd still want others to have agency. I'd still want to be able to have cancer.

I'd want it, simply because I can see God's love, manifest through peace, as well as the concern and love of others. Without it, I doubt anyone would be able to see the love of God.

So, here I sit, nauseous and queasy, happy that God is aware of me, while I listen to neighbors voluntarily step in and weed flower beds, mow lawns, and spray weeds in other areas. Just amazing care and concern.

April 10th

I actually just went through the start of round 2 (second cycle, two drugs). They re-ordered the drugs, and I didn't have the same pain. Perhaps that was purely because the blood work nurse that inserted the IV did a fantastic job. I don't know. It was better, but the same nausea is just as rampant, even if not higher strength.

However, the nausea and bloating did not end like I thought it would - it took more time before a proper bowel movement happened.

April 16, 2024

At 2:30 AM two days ago (April 14th), my arm once again became red, inflamed, swollen, and painful. After some discussion with the doctor over the next few days, it was determined that this was the result of Gemcitabine - it has a nasty habit of killing veins. On that discussion, it was realized that the pain foot print is the exact footprint of pain from when the Gemcitabine was first being administered on the 15th at full volume. Another swelling point has now appeared on the right arm (where the second dose of Gemcitabine was administered at half volume).

And, Sunday night (April 14, 2024), for the first time in decades, I threw up. Violently.

So, on the 16th, it was determined that I had to have a PICC line installed to prevent more failures of the blood veins. Yay for progress! After installing, the following chemo day blood tests were simply done at the time of the PICC installation.

The following morning (week 2 of round 2, Apr 17), it was decided because of the pain and swelling in the flesh of the arm that we needed to delay the gemcitabine infusion for another week (platelets were okay). This is a tender mercy, because I don't think I could have handled it. I've been experiencing some major PTSD this week. Instead, we headed back home and applied some topical anti-inflammatory to see if we can get the arm back down to where we need to be. The oncologist will look into what kind of gemcitabine is being used (freeze-dried had a 12-times-fewer instance of pain in Japan when compared to the liquid) at the facility, and determine if we can make changes there. He also discussed ending the 3-cycles a cycle early.

Well, the following day, I went in for an ultrasound on the arm. I have superficial vein thrombosis (SVT). That accounts for the swelling and pain. Now I'm on blood thinners, and my wife has banned me from tools that cut. [sigh]. That's the vast majority. Sometimes ya gotta be destructive before you can be constructive. Anyway, it took a few days of the topical cream and the blood thinners to reduce the swelling enough to no longer be excruciating. Now I can get back to normal.

So, back to the Gemcitabine. On the 24th, the drugs from Japan were in (freeze-dried Gemcitabine), so we could get that one started. Surprisingly, they ran it at full steam, and it did not have the same pain. This could be because of the drug itself, or it could be because we're using a PICC line. One side effect is that the bowels seem to function a bit better after this one, so I'm calling it a win. Sure, I still have the nausea, but it hasn't been as strong so far, either (this is added on the 25th, so only 24 hours after infusion). It was on the way home from that infusion that my wife kindly suggested a "playlist" for beating cancer.

AC-DC - Thunderstruck

AC-DC - T.N.T

Alannah Myles - Black Velvet

Alice Cooper - 01 - Poison

Backstreet Boys - Larger Than Life

Black Eyed Peas - Let's Get It Started

Bobby Mcferrin - Don't Worry Be Happy

Breaking Benjamin - 02 - I Will Not Bow

Christina Aguilera - 04 - Fighter

Chumbawamba - Tubthumping

Des'ree - 01 - You Gotta Be

Destiny's Child - 02 - Survivor

Diamante - Bulletproof

Diamante - Had Enough

Diamante - Haunted

Elton John - I'm Still Standing

Eminem - (Disc 2) 03 - Lose Yourself [Clean]

Europe - The Final Countdown

Evanescence - Bring Me to Life

Five Finger Death Punch - Wrong Side of Heaven

Fun. - 04 - Carry On

George Thorogood - Bad to the bone

Gloria Gaynor - I Will Survive

Guns N' Roses - Welcome to the Jungle

Hall and Oates - 06 - You Make My Dreams (Come True)

Heart - Alone

Imagine Dragons - 10 - Thunder

Imagine Dragons - Radioactive

Jenn Johnson - 09 - You're Gonna Be Ok

Jessie J - 13 - Who You Are

Journey - Don't Stop Believin'

Kansas - Hold On

Katy Perry - 01 - Rise

Kelly Clarkson - 02 - Stronger (What Doesn't Kill You)

Kristin Chenoweth, Idina Menzel, Ensemble - Defying Gravity

Lawrence - 01 - Don't Lose Sight [Explicit]

Lee Ann Womack - I Hope You Dance

Metallica - Enter Sandman

Metallica & SanFran Symphony - Enter Sandman

Miley Cyrus - 08 - The Climb

Muse - Uprising

Nickleback - 06 - Burn It to the Ground [Explicit]

Ozzy Osbourne - Crazy Train

Papa Roach - 04 - Born For Greatness

Pat Benatar - Hit Me With Your Best Shot

Pink - Get The Party Started

Pink - So What

Queen - Another One Bites The Dust

Queen - I Want It All

Queen - The Show Must Go On (with Elton John)

Queen - We Are The Champions

Queen - We Will Rock You

Rachel Platten - 05 - Fight Song

R.E.M. - 06 - It's The End Of The World As We Know It (And I Feel Fine)

R.E.M. - Everybody Hurts

R.E.M. - Losing My Religion.mp3

Roxette - Listen To Your Heart

Shinedown - 10 - A Symptom Of Being Human

Simon & Garfunkel - Bridge over Troubled Water

Sixx:A.M. - 05 - Rise

Survivor - Eye of the Tiger

Taylor Swift - 06 - Shake It Off

The All-American Rejects - 03 - Move Along

The Beatles - Let It Be

The Cranberries - Dreams

Twisted Sister - Were Not Gonna Take It

And, a Spotify link to the list :

Spotify - The SilverHawk "Beat Cancer" Playlist

Turns out to be an interesting play list. (I did later add Michael Jackson's "Beat It" and the Bee Gee's "Stayin' Alive", M.C. Hammer "U Can't Touch This"/"Too Legit to Quit" and Softcell's "Tainted Love" among others.) There are too many things that can be mentally tied to cancer, and they just crack me up.

Anyhow, this form of Gemcitabine seems to be much easier on the system.

April 26

Friday rolls around, and I get news from HR that they've rejected my FMLA. So, I start digging in. Turns out the HR person thought I submitted the wrong form. A little back and forth, and suddenly, I've been approved for FMLA. But there is a lot of request start and request stop notifications. And, since it's going to come out of paid time-off anyway, I might as well just do FMLA once in a while (go unpaid to preserve some PTO for when I'm healthy to celebrate), and just PTO on the other days. Yay for awkward situations.

May 1

The off week seemed to be business as usual, with neighbors stepping in to take care of the front yard. I must say that it is a miracle that we are surrounded by such amazing people.

May 10

It's been a while since my last update. We've done the first week of the third round (May 8, Gemcitabine and Cisplaten), and we're getting ready for the second week's dosage (the 15th). However, those SVT's are back with a vengeance. In fact, I now have another one in the right elbow, immediately at the confluence, and that is kind of panicking me.

I went through the ringer today trying to get appointments squared away, though. We moved the radiology oncologist appointment, delayed the colonoscopy appointment, and also cancelled the heart stress test (and subsequent cardiologist appointment). Sheesh.

May 16

After the second week (Gemcitabine) dosage yesterday, I was pulled in for an ultrasound. The radiologist was concerned about not as much the right elbow as he was the PICC line. There was no compression on the vein for that. The doctor did not even mention it, so I guess I have to be okay.

This round has been a little rough. Cognitive function was much lower (ability to concentrate, in particular). It made a rougher day of work, especially with so many folks yammering for their particular piece of my work day. At least I know I have a job still.

June 1

Forgive me, it's been a few weeks (it's now June 1st, so I've had my off week and a week of scans). The PET scan this past Tuesday morning was labeled "significant partial progress". It sounds really awkward, but yesterday (Friday), we spoke with the oncologist. He put that into terms I could understand.... only if the cancer is fully cleared and gone can it be anything but partial. Significant means that the progress is not done, but the initial treatments were obvious to the radiologist. In fact, those lymph nodes that were highlighted in the first PET scan back in March all seemed normal and clean, except for two of them, and those showed a major decrease in size, too.

It seems that the first three rounds did exactly what they needed to, and had a major impact.

Now, it was guaranteed that I'd be facing another 6 weeks of chemo along with radiation. That can potentially start in the next week or two. But it is only going to be 6 weeks, not more.

The radiation will be each week day, and the chemo will be Cisplaten once per week. The volume of Cisplaten will be decreased as well (that was the drug that was given once every three weeks). The chemo is only to aid the radiology in doing it's job. The oncologist said that the first two weeks will be uncomfortable, the next two weeks miserable, and the final two weeks I will probably want to die. The radiology will focus on the neck (obviously, that's where the cancer is), and will make my throat feel like major sunburns. It's going to make it hard and painful to swallow anything, so he mentioned four keys :

- Hydration - I should be getting 64 fluid ounces of water per day.

- High calorie meals, in any way I can get them. Some people hurt so much on the throat they require feeding tubes. If body weight decreases by 10% in the first three weeks, they'll put me on feeding tubes, so I MUST make sure to maintain weight.

- Exercise - I need to get up and move around.

- Bowel movements - I must make sure everything is moving like it should.

This is going to be a "fun" road to walk. I should be done by late July, and that means I'd have 6 weeks to heal, but 3 months before inflamation has died down to allow good PET scan results - meaning in theory, the end of November I might be free of cancer.

June 6

Every week, I have to get the PICC line dressing changed. Over the course of a few months, the bandage to keep things clean and pure (it's a straight conduit to the heart) has been getting terribly itchy. I finally told the nurses changing the dressing, and when we pulled the dressing off, we had reactions.

Why am I so stubborn that I waited this long? They changed away from Chlorhexidine (which was reacting with my skin) to Betadine dressing.

June 12

Sure enough, moving away from the de facto standard of Chlorhexidine solved the itching problem. Betadine was the way to go for me.

It looks MUCH better after one week!

July 7th

Okay, the "schedule" they provided about uncomfortable-miserable-death is right on. 10 days into that, my taste started to scram. Two weeks in, I started to struggle to swallow. Within 4 days of that, I was experiencing dehydration. Bloody throat, mouth tissue splitting, and exposed nerves along the throat are making this a rockin' good time. I find myself with no appetite (who wants to eat when it just hurts, and nothing has taste?).

I know I need to consume calories, so breakfasts become things like Malt O Meal wheat germ cereal with ice cream (to increase the caloric intake). My meals are slow and small.

They prescribed a "magic mouth wash" to numb my mouth. Every time I take that, I throw up. Gag reflexes are at an all time high. Saliva is thicker than normal boogers, and that just messes things up even more. Yes, this is the real deal. In one week, I'll hit that 4 week mark where things supposedly go from "miserable" to "I'd rather be dead". When that happens, it could be time for a feeding tube. Maybe I can get a breathing tube, too. Probably not, because a trache might interfere with the stupid radiation. [sigh].

July 16

While in getting dressing changed, remember all of those SVT (blood clots)? I thought I'd grab a picture of the confluence one from months ago.

It is still around, but the vein was killed. The picture above doesn't really show much, but the vein leading up to the confluence is brown. It's also fairly rigid and hard.

July 22nd

It's been a few weeks since my last update. I gotta tell you, that "schedule" of Uncomfortable-Miserable-Death is real. We're one week in on the "wanna die" phase. There is nothing like coughing up blood, dry heaving more blood, and having so much grit on the back of the throat that you simply do not want to eat.

So, last Thursday, I've received an "NJ" tube (nasojejunal tube that runs from outside of the face through the nose and into the jejunum of the intestines.

The criteria for a feeding tube is 10% of your body weight being lost. I hit that pretty solidly last week.

So, after a weekend of using the tube, my weight loss has stabilized. A

few more data points and we'll know if I'm trending in the right

direction. Caloric intake has risen from 300 calories/day to about 2000, though the doctors want another 1k calories being fed in. We have to slowly build up on the rate of the feeding tube so we don't incur the wrong side effects (requested a 120ml/hour, last night was 88.2ml/hour).

The plus side is that it bypasses the stomach, alleviating some of the nausea. It doesn't solve it all, though. I can't swallow, which means primarily that I get the gagging done anyway because of the thick saliva and the inability to properly clear my sinus of mucus.

Open sores and ulcers, nothing in the stomach (so that hurts, too), and having a new tube strapped to my face makes this a bit more interesting. We're nearly complete, though - we finish chemo in 8 days, and radiation in 11 days. Granted, it's not a guarantee that we're finished - we have to wait until the swelling and inflammation has dropped enough to do a PET scan (likely in November). The targeted milestones :

- July 30 - last day of chemotherapy

- August 2 - last day of radiation

- August 23 - shifting from wanting to die to just being miserable

- August 30 - taste should start returning

- September 6 - shifting from miserable to uncomfortable, sores likely healing over, potential tube removal

- November - PET scan to know for sure

Two more weeks of misery before I can have a few more weeks of misery. Yay!

July 26

Well, some more neighbors crashed the "help" scene. We've had a higher water bill this year, and they found out why - the release valve went south and filled the sprinklers manifolds to the top with water.

So, an absolutely kind neighbor spent two days rebuilding our front valve and sprinkler setup. He would not let us pay for parts or labor. This is yet another miracle.

July 30

The last few days have been excruciating, and not just because of pain (in fact, the pain has been the least of the problems).

Mucus.

Maybe that should be my new name. Coughing fits to try and clear throats, and immediately bringing dry heaves into action. I must say that I should have a 6-pack of abs when this is done. My poor tummy has been just pulverized.

The mucus is simply gross. It smells like dirty feet, so the ONLY smells I get are dirty feet, poop, and mold. I have progressed to a point that I disgust myself, and it's not pleasant in any way. The mucus is thick, dark brown (and or red from blood), and the feeding tube does nothing to ease the expactoration of it.

However, being the 30th, we've now finished the last day of chemo. My wife made me ring a bell (to me, it really didn't matter). We're not "done" until Friday, the 2nd, so it felt a little early to me. Oh, well, she has much skin in this game as I do. It means that she has as much claim to that bell as I do. So, I will ring it.

And then we'll ring it again on Friday.

July 31

We have the milestones now.

Aug 2nd, last day of radiation.

1st week after will be the worst week of it all as things continue to open up from the radiation.

2nd week after will have the sunburn healing (skin easing on the red)

3rd week after the pain will begin to subside. This week should be the migration of wanting to die to just being miserable. Swelling should also begin to subside.

4th week after, mucus will begin to return to normal, and taste will start back up (but will be interpreted rather oddly because the body is definitely not used to it - e.g. things will taste different, or wrong).

5th week - shifting into uncomfortable. At this point, sores in the throat should be healing up, and pain in swallowing should be minimized, allowing the potential to move to eating real things.

August 2

Today was the last day. Gagging is high. Exhaustion is extreme. This is one experience I will be glad to have done. I did hit the gong and the bell for both chemo and radiation.

My strength is failing. My timetable is what I'm holding on to - I didn't come this far to quit. There is zero appetite for anything.

The nausea has caught up - I ended up dry-heaving, then tossing morphine, stomach acid, mucus, and blood for 5 minutes. What made it worse was the fact that I was sitting on the great white porcelain throne (toilet) when it all hit. I can't clear the sinus or throat, so I'm stuck with the acid burns on top of the radiation ulcers. Joy.

But, I did manage to fix some sprinklers, so I'm calling this day of ground zero a success!

Aug 9

I waited intentionally for a week. Doctors called this one of the worst weeks of the process. This has been validated.

- Sores are still opening up

- Swelling is not dropping (we knew this ahead of time)

- The sunburn has not diminished yet

- Mucus production has been through the roof, and the mucus constantly contains both fresh and old blood

- Mucus production leads to volatile dry heaving as the body tries to clear the throat so you can breath

- The whole mouth aches terribly (even teeth)

- Swallowing is at an all time pain high, requiring controlled substances to maintain some sort of sanity

However, there have been some good signs. Two days ago, over night, it felt like I'd suddenly hit a plateau, meaning the swelling stopped increasing, and the mucus production seemed to hit a constant rate (instead of increasing every hour). I fully expect that (now that I'm officially starting week 2) the sunburn will be the first to go. We've been using a combination of Cetaphil and Aquaphor, hoping to alleviate one issue. The more issues we can fix, the better the body should be able to focus on healing the other parts.

Aug 10

I'm adding out of the every-week cycle, simply because of changes. The mucus seems to have slowed drastically, and some of the sores have started to heal over. We had that pegged as week 5, but it is day two of week two, so I think my body is just healing quickly. This is fantastic news.

Mucus has had fresh blood for a while now, and now it is coming with a combination of fresh blood as well as old blood. Some is red, some is dark red, and also nose boogers are becoming hard and crisp, like scabs finally starting to peal off.

The pain of swallowing seems to have only slightly diminished, with more pain on my tongue (where it feels like I bit it - that has been a painful spot for a while). So, even though week two is supposed to be "wanting to die", that glimmer of hope and the faint bit of recovery has shifted my psyche already. Woohoo!

Aug 16

This has been a whirl wind of a week. Yes, things started improving. Around Monday, pain for swallowing had dropped significantly (yet another miracle), and the mucus was drying up. Swallowing had shifted from excruciating to barely bearable, but that was a HUGE shift.

Then, on Wednesday, the oncologist did his examination, and panicked. I don't have Thrush, but he said, "just in case" and threw a prescription at me. Four times a day, for seven days, I have to rinse my mouth out with this. We're 24 hours into the prescription, and I've learned one thing....

... four times a day for seven days, I'm going to have violent reflexes as my body continues to cough this damn medicine out. It's a rinse-and-swallow, OR a rinse-and-spit. I can't even get to the swallow before my body is tossing cookies I haven't even consumed. And this tossing of the said cookies is brutal, and goes on for 5 minutes.

Doc said "try diluting it". No change. I'm glad my wife took a weekend with a friend to go and relax, because this will reduce the amount of time she has to hear me trying to expectorate a lung. I keep coughing up bloody mucus.

However, aside from this every-4-hours reflex, things aren't bad. No taste yet, and swallowing does still hurt. When that pain subsides, I'll try a little ice cream here and there (not even a teaspoon) until (a) my taste returns, at which point I'll start increasing the amount until (b) my stomach can handle it. It has been five weeks since I've had anything substantial, really, so I know the stomach will take time to recuperate.

Aug 24

Yesterday was the three-week mark. The day before I finished that ugly medicine. I've dealt with clogs. I can smell (at random times), I have a constant ringing in my ears, and my mouth has gone from mucosal to very dry. I've started sipping water lately, and we went to a speech/language therapist who made me eat quite a bit of food. My stomach has been upset ever since. I have to blow my nose every time we do a feeding tube line flush just so I can continue to breathe. It's not wanting to die, but it is miserable, just like they said. Next week should start the healing processes, but the last time we looked at my bloodwork, the red and white blood cells were still very low (hadn't recovered). So Friday's "hydration" infusion included vitamins. It seriously looked like I was being given an IV of mountain dew.

Aug 28

We hit an odd snag. The feeding tube clogged. While we've been able to clear this in the past, we tried for 48 hours to clear it. At that point, we spoke with the oncologist about simply removing and trying without, and then with the dietician as well. Both concurred that we might as well pull it, and if we can't get the nutrition, we can get it put back in. We DO know that they'd have had to pull it before putting one back in, anyway, so we're simply starting this process a wee bit early.

As to being able to swallow, the problem we've faced was the pain in the past as well as not having taste. (Seriously, why eat if you can't taste the food or enjoy the texture?) I, in an attempt to "detect" when taste returns, have been putting a drop of maple syrup or honey on my finger tip, and then running a test.

That little test began to show signs of life on Monday, the 26th, so hope has arisen. Granted, that was very fleeting (taste was gone within an hour and didn't return that day), but again, bright and early on Tuesday (when we detected the feeding tube clog), taste was back, albeit again, fleeting and diminished (the first one probably shocked me more than anything). It returned later that night, and has been hit and miss since (not scheduled for mornings only). When we did a hydration, I had a blue raspberry jolly rancher, and that taste was hit and miss (took me a few hours to finish it).

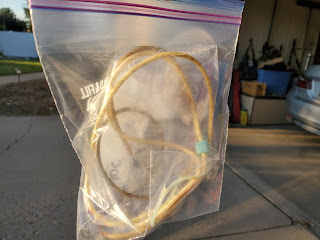

So, arriving at this point, it's pretty clear that the tube was being worthless, and if I can get by without, I'm that much better. So, I pulled it (just like my stitches - on my own and in privacy). I double-bagged the feeding tube - that was disgusting to remove. Just the sight of it triggered nausea, which the nurses did warn me about (they were kind enough to say that I needed to be somewhere close that I could puke).

The tube was approximately 54 inches long (nearly 5 feet), or 136 cm in length.

We've been consuming 2000 calories nightly with the tube just to maintain weight, and the doctor said to get that in half as the first goal (dietician confirmed), then work from there to get back to the 2000 calories (and potentially more).

So, my first objective is to figure out how to consume 1000 calories. I've been given hints by the dietician such as :

- Avoid clear liquids (other than water, because of the potential for choking on it while re-learning how to swallow).

- that cream of wheat cereals are okay, with lots of fat added (ice cream added is a good thing).

- Things with potent flavors will help get past the minimal taste issue (things like onion, garlic, etc). I'll vouch for this - I added garlic salt to some cream of chicken soup, and the before and after were definitely different!

- Fruit nectors (not juices) are thicker and good.

- Any cream-of soups are okay (cream of chicken, etc - I didn't know they made a cream of bacon or cream of potato, or even a cream of asparagus, I'll try them and see).

- Overcooked noodles are a plus. If needed, add butter, but don't hesitate to use any cream-of soups with the noodles to increase calorie count.

We've been doing hydration three days every week. Last Friday, I thought something was wrong because the stuff they put up looked like Mountain Dew (I wish I could taste some right now).

|

| The yellow bag on the IV - forgive the hat, I was using it to block out neighboring patient info |

But, it is just hydration with vitamins (B1. etc).

The cream of chicken soup only has 130 calories. Damn. To get to the 2000, I'd have to eat 15 of those things a day. Luckily, I have other options, and I can't eat one (only 1/4th of one, so about 30 calories). I might add a snack pack pudding (90-100 calories), just to add intake, for a nightly meal. I KNOW I'm going to have to schedule things on my work calendar through out the day to remind me. It's been 6 weeks since I've really had much, anyway, up until the swallow therapist almost force-fed me a week ago.

So, this will make for an interesting few days.

Sept 6

We went in to the speech/language therapist, and ran through a barrage of tests while my throat was scoped. No pictures of the sinus (where I still have discomfort swallowing), but the throat looks good. In fact, the therapist said the swallowing was in good shape, and she cleared me to eat anything. I know I still can't, but I'm taking steps. We moved from liquid/puree to soft food (I ate some refried beans). Hopefully next week I can progress to some more solid foods.

Sept 10

Well, it's been a while since I've had a good, detailed post (skipping the last one, it's been what, 12 days?). The caloric intake has been to the 1 kilocal state, so I've at least gotten to the bare minimum. I still have little endurance, and I don't know if that is the calories, or if that is simply because we nearly killed the body (that's what we do through this process).

So, that's a good sign. As to the other tube, I went in for hydration yesterday, and was told we didn't have an order for it. So, I did not get hydration. However, over the last week, I graduated from the tiny toddler cups to the regular glassware, and I think I'm okay. If I can maintain this stance, it means I can probably have the PICC line removed in the short future. I was told by nurses that the PICC line usually heals within 24-48 hours, so depending on how strapped my body is for healing, I could potentially be able to shower without a sleeve as early as next week (I'm guestimating here, there is no medical timeline provided).

So far, keeping myself hydrated is working. It seems like my body is slowly returning to normal (I know I still have a long way to go, but progress is progress). In fact, this morning, I could actually TASTE SWEETNESS, which is one of the last hurdles I have. It is minimal (I could barely taste it, and it didn't last long before I couldn't taste it), but it is a step in the right direction. The next step I have is being able to eat breads without it feeling coarse or abrasive on the back of the throat when swallowing. Hopefully that comes this weekend.

So, my next goals are :

- Swallowing breads

- Eating chips and crackers

- Start regaining strength

I need to keep this one going!

Sept 12

Well, after meeting with the oncologist yesterday, and not having hydration for nearly a week, they ordered blood tests to make sure the kidney function was still good. And, once it turned out to be good, the doc told me I can come in and have the PICC line removed.

|

| Before removal |

|

| After removal |

I no longer have medical tubes keeping me alive!

My water levels are solid, my caloric intake is not good but not bad, and the doc has cleared me until after the next PET scan is run, so I don't need to see them for a few months. The amount of time to see doctors is spreading out and clearing!

I do still have ulcerations in the mouth and sinus (oncologist acknowledged them), so I have to keep things to soft foods for now, but slowly making progress!

Sept 14

We pulled the bandage covering the PICC line hole (it's been over 24 hours, the nurse said this was okay to do). For the first time in months, I can take a shower without some weird sleeve on my arm that I have to prevent from getting wet.

Granted, this was gross when pulled (similar to the mucus). If you look closely in the photos, there is a "strip" of yellow, pliable-but-gelled gunk. When pulling the tube, this was in the vein, and it stretched, and then snapped out of the arm into the bandage. While gross, it was pretty cool to witness.

The milestone feels like I'm progressing, even if I don't actually feel like it. Still have some swallowing issues (I have homework from the speech/language therapist for swallowing exercises), so I'm working on that. Gotta keep going!

Sept 29

The last spell was... interesting. Went to church two weeks ago, and caught some sort of virus. That set me back, for sure. While I'd normally be back to normal a day after feeling all the things a virus does, this one took a full week before I turned the corner and started feeling better (which happened this past Tuesday). Last week, in the middle of this, the oncologist said "go to the instacare immediately" - I guess I still have an immune system that is scraping the bottom of the barrel.

So, I went to instacare - who ran one single test - only to find out definitively that I do NOT have COVID. No other tests, nothing was done. It's viral (symptoms, which I'd already determined, and we ran a COVID test at home a day before so we knew it wasn't that already), but we don't know what virus it was.

So, since the medical providers cared less about determining what virus an immune-compromised cancer survivor had, I determined that it was a matter of wait it out and hope it doesn't get worse. 3 days later, I stopped getting worse, and 2 days after that things started to finally get better (this past Tuesday).

On Wednesday, we went to the radiation oncologist, who scoped my sinus. Lots of gross mucus still in the sinus, but the r.o. determined that there is no outward (if you can call the inside of the sinus that) sign of cancer. That doc now thought there was no need to visit until after the PET scan, targeted for early November. This is good news as it means that October only has to deal with the Speech/Language Therapist and also the Lymphadema Therapist. The second one has had one appointment, and only one more is likely needed (in two weeks).

Caloric intake has stalled at around 1.5kcal per day. Friday took a beating because of some health issues, but yesterday, it was pushed to 2.3kcal . I knew I needed calories, so a Five Guys burger, fries, and a shake was where I ended up (I tried for simply some waffle fries and chicken from Chick-Fil-A, but lines were too long and they had their inside ordering shut down). I was already nearly at 1.5k before the burger. I scraped everything off of the bun, only ate 1/3rd of the fries, but I did eat that shake. That managed to put me in caloric intake higher than I've had since the feeding tube.

Taste is back, sort of. There is a mingled taste after a few bites that is still causing things to not taste good. The Radiation Oncologist called it "metallic", and I can see how it could be considered a metallic taste, but it's not quite metallic. It's hard to describe. It is the taste buds still waking up. A few "chews" of a good taste, and then this one is back. I hope that if I continue to chow down on things and force volumes, that will go away.

Well, that and the mucus being removed. Yesterday, I nearly threw up as my body was trying to clear a small piece of mucus. Two cough-ups of dark brown mucus (yay! A little more!), and then while working with the laser cutter, a little more in the nose caused me to run for the bathroom to blow my nose.

It was thick enough, that when it came, it brought a lot more with it (and I am celebrating that one). The extricated mucus was about the size of a quarter in every dimension, plus there was a chunk of hard scab with a curved gap in it from the feeding tube of so long ago.

|

| I never thought I'd be posting pictures of boogers. |

One more ulcer has been healed! I think I'm nearly there where my body can start to focus completely on regaining strength and endurance!

Oct 5

Okay. This has been a week of progression. I still suffer from something similar to "orthostatic hypotension", which is what typically causes you to feel light headed, as if you are going to pass out when you go from a laying or sitting position to standing. Is that what I have? I have no idea. But, the symptoms match up. Causes are lengthy bed rest (which I don't really have a problem with) or dehydration (which I also don't have a problem with - I experienced the issues when I was getting hydration at the chemotherapy fusion center). It can also be caused by anemia, which I know I'm dealing with a little bit, however, my oxygen/O2 stats have been high 90's for the most part (e.g. I'm averaging a 98% oxygen saturation), so I really don't know what could be causing it.

Aside from that, and lacking in endurance, I'm doing better. I had the flu shot on Thursday (under advisement from my oncologist - make absolutely certain you consult with your specialist in a timely fashion). That caused weird reactions (I know, I'm supposed to wait for 10-15 minutes after the shot to make sure there is no reaction, but I knew I'd feel it later and simply left to get home quickly before other effects hit). For example, when vision flashes, or patches of your eye sight go white blind like you stared at the sun too long, if you have a migraine - yeah, that, but without the pain and aches of a migraine. It was weird.

I ate alphabet soup, so I've had good vowel movements (sorry, I just HAD to work that in). Speaking of vowel movements, since I've added other dietary things like a hamburger or fries, or a pizza (yes! It was divine!), that's improved. For example, I had a chicken burrito last night with some habanero spice to it. That was also delicious! And today, my dad brought me apple crisp. This isn't your normal apple crisp that has oats in it (I'm allergic to oats), it's an amazing substance.

We did find out this week that because I haven't been drinking our Mountain Dew, it's all expired. And this is stuff that is difficult to track down (it's the "real sugar" stuff, and in this area, it is rarer than hens teeth). If it tasted normal, I'd still drink it, but it tastes like it's expired. Also, I found out that Pepsi no longer makes the stuff. [sigh]. I stop drinking it and a few months into that they stop making it. I know for certain that I wasn't keeping that branch of production alive, but it does feel that way.

I still do have that "metallic" taste. It hits at random times while eating, but I'm forcing myself to eat. This past week, I averaged 2,156 calories per day, which is a huge win (the feeding tube was averaging 2,000 calories per day for reference). My weight has not only stabilized, but started climbing (up to 186 lbs from the previously-stable 183 lbs).

And, get this.... the bald patches of my jaw, the top of the back of my neck, legs, and crotch (yes, I did not expect hair loss in the crotch area, that was a bit of a surprise) has just barely started to grow back. My mustache is very salt-and-peppery, my hair has definitely gone gray through all of this, and that is just the stuff that stayed. I've been told that hair is more curly (which could be bad with me because I already had very wavy hair if it got longer), because the pores are very flattened after the chemotherapy. That's another thing we now get to witness the truth of.

Oct 30

It's been a few weeks. The taste issues have come and gone. Nothing is set in stone, so there is still hope. However, a few weeks back, I had a flu shot. I've had a congestion problem ever since that point. Additionally, my feet (tops and bottoms) have been tingling, and the last few days I've had swelling in my feet (painless, but weird). It might be classified as a peripheral edema (a side effect of Gemcitabine). I'll message the doctor to see what he says.

Nov 13

This afternoon, I met with the docs to review a PET scan. The news is official - I have been declared cancer-free! This is a MASSIVE change. I am not even close to 100%. In fact, I'm not even close to where the docs said I'd be (they said around 70%-75% back to normal in December, I'm more around 50% as of right now). I still struggle to eat (it's a chore to me, not something that is pleasurable). I still have the Neuropathy (tingling in my feet) and the swelling. I still have that awful taste that comes and goes and clouds things. I still have balance trouble. I still have the broken baroreceptors in my carotid artery that help the body self-regulate blood pressure (which makes the world spin when I stand up, some of which is pretty bad and takes me to my knees so I don't fall). I still have patches of beard that doesn't grow. I still have the tinitus (ringing in the ears).

All of these issues are side effects, and may or may not be permanent.

But I'm CLEAR. And that's enough.

Some folks who experienced head/neck cancers at the same time haven't had swelling go down far enough to be able to have their PET scan. Some are still struggling to even get as far as I have. I know that there is a power in prayer, and blessings do follow you when you seek God.

My weight dropped from 217 lbs down to 188.4 (low was around 182).

My caloric intake has been hard hit - but I'm keeping it around 2k calories.

And my A1C has settled - even after the sugar/glucose intake trying to meet my calories - back down to 5.2 (was at 7.3 in May).

But I'm GOOD!

Stuff we've learned :

- What hair that doesn't fall out does get brittle and breaks off easily

- Chemotherapy slows down everything (nails grow slower, wounds take longer to heal, etc)

- For nasopharyngeal carcinoma (stage 3 in the lymph nodes in the neck), when the doctors say the first two weeks of radiation will be miserable, the subsequent two weeks (three and four) will be miserable, and the next two weeks (five and six) you will want to die, they are dead accurate (no pun intended)

- You will lose weight when you can't taste, and swallowing hurts - do NOT hold back on getting a feeding tube to get you through it

- When the radiation oncologist says that (after the radiation is done) you will have the six week schedule in reverse, it is absolutely true - first two weeks of wanting to die, two weeks of misery, and then two weeks of discomfort

- If you experience a complication (such as a virus), know that your body cannot do what it would normally take a day or two to recover takes two weeks, and your body doesn't heal during this period - it seriously takes you back

- If you feel like you are getting sick, go to the emergency room (wearing a mask, of course), and do not settle only for a COVID test - make them determine what you actually have because that could result in medication that can help you through it faster

- Do not expect taste to suddenly be back and normal - it took an extra two weeks after the discomfort for it to start, and I couldn't taste sweet things for a long time (it's still diminished, but a few weeks after that, it's starting to show up)

- Once the six-week-after periods are done, you are not "normal" - your body still has a very compromised immune system, your stamina is still in the toilet (where your immune system is, surprisingly), and you can't just go back to doing normal things - you need to start from square one and work back into things, and that progression takes time - two months after finishing chemo/radiation, I'm probably about 20% of normal

- Expect that moving from sitting to standing will have fainting, dizziness, and lightheaded symptoms for a long time

There is one thing I'd list in the "learned" section, but this is simply too big to go with the lesser stuff above.

Take time to find the small miracles. Trust me, you NEED this. God is a God of miracles, and even if He doesn't make the cancer disappear, He WILL walk with you through this challenge. He will bless you with small things, like neighbors who step up and bring in garbage cans, or weed a small flower bed. He will bless you with people who are going through the same challenges - reach out to them so they know you care, and they'll do the same. You will form strong bonds and new friendships. Families grow closer together.

Just find those little miracles. They are there.